This was an individual project assigned to me during my co-op work term at Tigercat Industries Inc.

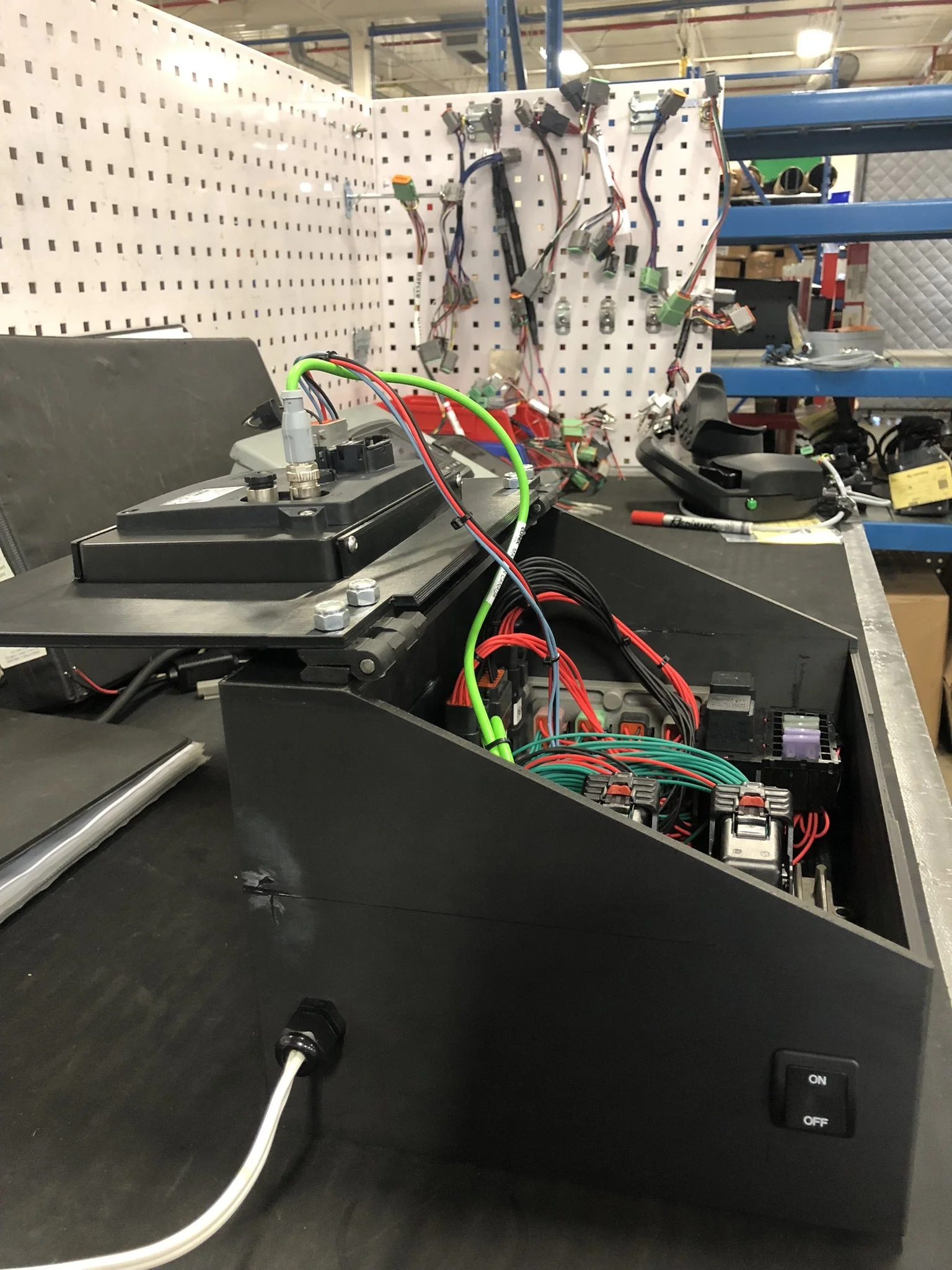

The main objective of this project was to replace their current Joystick Testing System due to a lack of available memory and limited input capacity. Using the same readily available components, tools, and software platforms that make up the machinery manufactured at Tigercat, I successfully designed and built a new touchscreen Joystick Tester within three months.

This new Joystick Tester is used by Tigercat daily, Key features include:

Simple and efficient user interface with keyboard search and numerically sorted scroll wheel for test selection

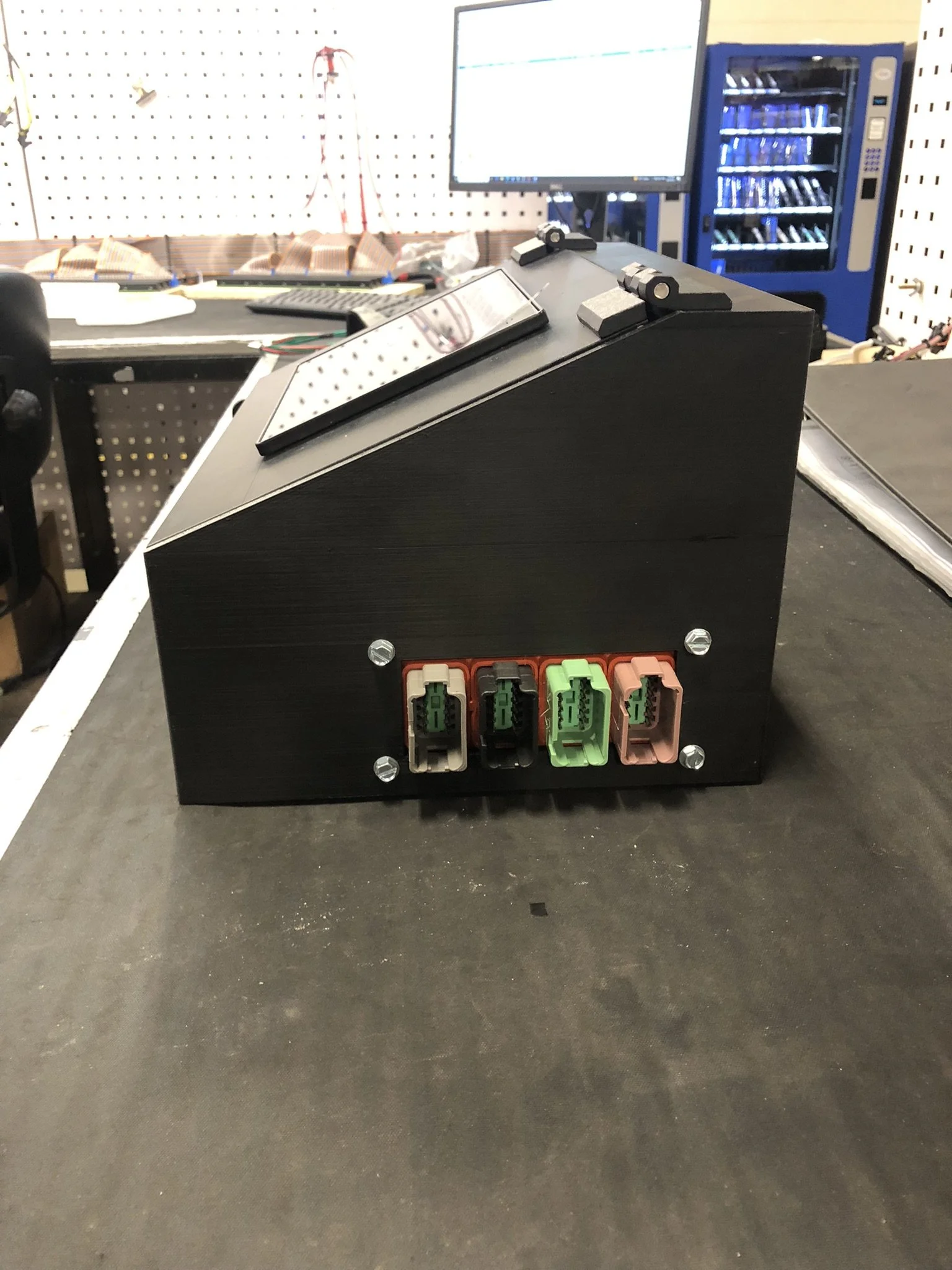

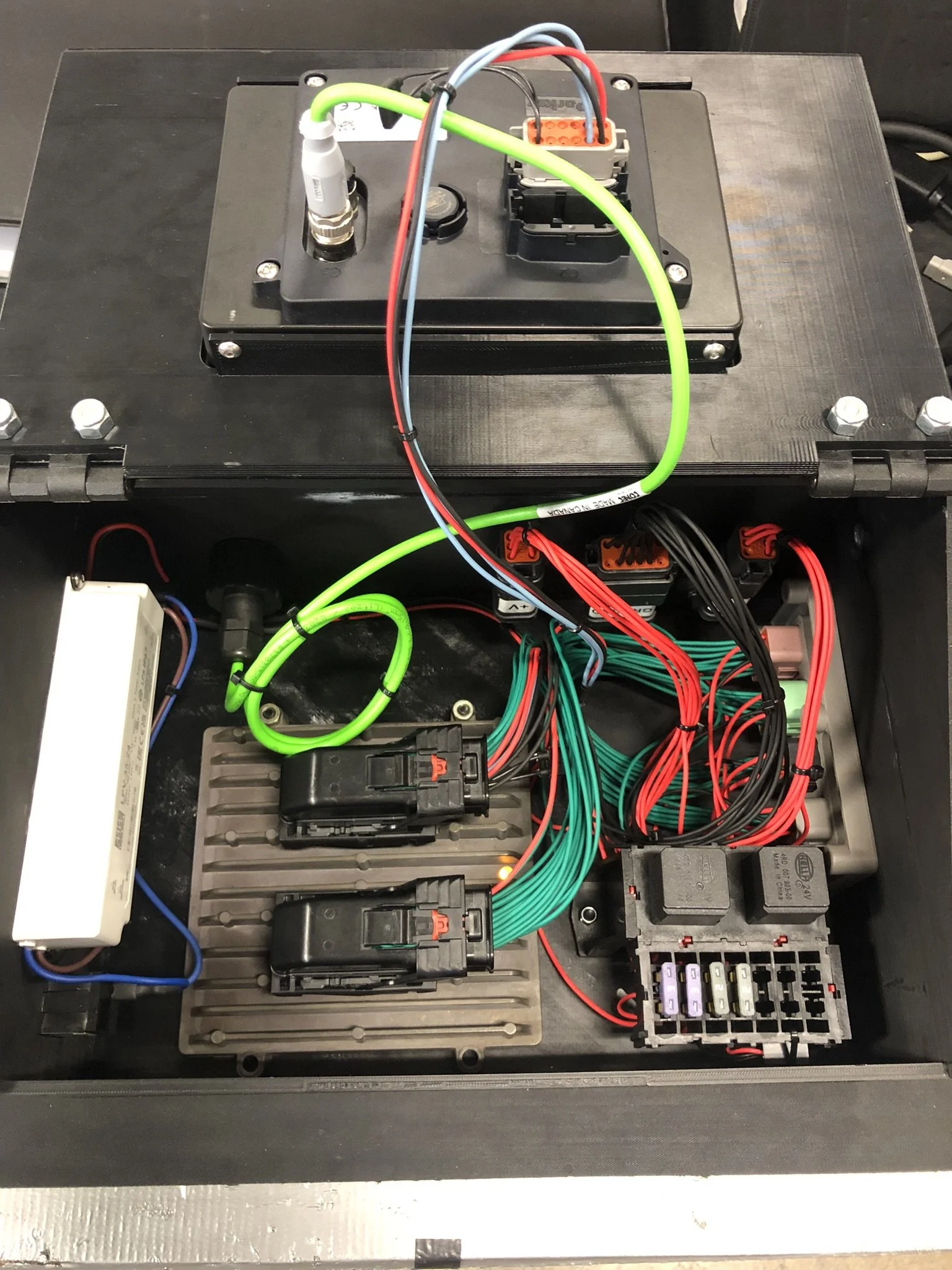

Four independent test harness connectors combined for a total of 36 digital, analog, and current inputs

Memory optimization through a multi-master system and purpose-specific software for each module

Smart relay-actuated variable voltage output based on test selection and component requirements

Custom 3D-printed enclosure

Easy access to the ethernet connector at the rear of the enclosure to streamline the software update process

Relay actuation tests along with a “Measure” page displaying all input values for live debugging or troubleshooting

Joystick Tester